GRP Pipe Seals: A Comprehensive Overview

Introduction:

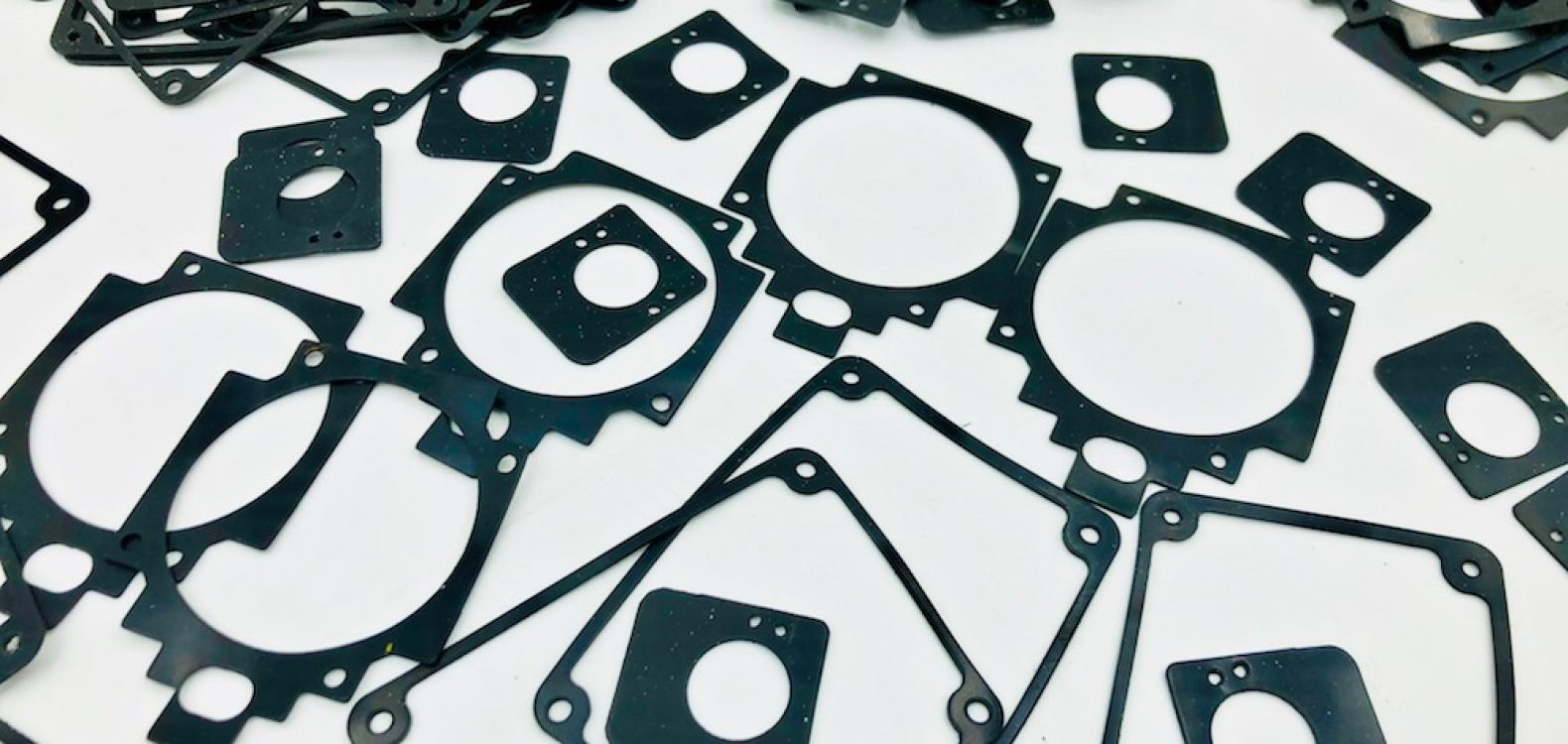

GRP (Glass Reinforced Plastic) pipe seals are specialized components used in the installation and maintenance of GRP pipes. These seals play a crucial role in ensuring the integrity of the pipeline system by preventing leaks, providing structural stability, and accommodating movement due to temperature variations or ground settlement. This comprehensive description will delve into the key features, advantages, applications, and installation considerations associated with GRP pipe seals.

1. Key Features of GRP Pipe Seals:

- Material Composition: GRP pipe seals are typically made from a combination of reinforced fiberglass and resin. This composite material offers exceptional strength, corrosion resistance, and durability.

- Corrosion Resistance: GRP is inherently corrosion-resistant, making it ideal for use in harsh environments, including chemical plants, wastewater treatment facilities, and marine applications.

- Flexibility: GRP pipe seals are designed to be flexible, allowing them to accommodate the movement and settling that can occur in underground pipelines. This flexibility helps prevent the pipes from cracking or failing under stress.

- Sealing Effectiveness: The seals are engineered to provide a reliable and long-lasting barrier against leaks, ensuring the integrity of the pipeline system.

- UV Resistance: Some GRP pipe seals are formulated to resist the damaging effects of ultraviolet (UV) radiation, making them suitable for outdoor installations.

2. Advantages of GRP Pipe Seals:

- Leak Prevention: The primary function of GRP pipe seals is to prevent leaks, protecting the environment and conserving valuable resources.

- Structural Integrity: These seals contribute to the structural stability of the pipeline system by absorbing vibrations, accommodating ground movements, and preventing joint separation.

- Longevity: GRP pipe seals are known for their durability and long service life, reducing the need for frequent replacements and maintenance.

- Chemical Resistance: They are highly resistant to a wide range of chemicals, making them suitable for use in chemical processing plants and other corrosive environments.

- Easy Installation: Installation of GRP pipe seals is typically straightforward, reducing labor costs and installation time.

3. Applications of GRP Pipe Seals:

- Wastewater Treatment: GRP pipe seals are commonly used in wastewater treatment plants to prevent leaks in sewage and effluent pipes.

- Chemical Processing: Chemical plants rely on GRP pipe seals to maintain the integrity of their chemical transport and processing pipelines.

- Marine and Offshore: These seals are suitable for marine applications, including offshore oil rigs, due to their resistance to saltwater and harsh environmental conditions.

- Infrastructure: GRP pipe seals are employed in various infrastructure projects, such as bridges and tunnels, to ensure the reliability of drainage and sewage systems.

- Industrial Pipelines: In industrial settings, GRP pipe seals are used in pipelines for conveying various liquids, including corrosive chemicals and industrial wastewater.

4. Installation Considerations:

- Proper Sizing: Selecting the correct size of GRP pipe seal is crucial for an effective and leak-free installation.

- Surface Preparation: The pipe surfaces should be clean, dry, and free from contaminants to ensure a secure seal.

- Tightening Torque: Follow manufacturer guidelines for the recommended tightening torque to achieve the desired compression and sealing effectiveness.

- Environmental Factors: Consider environmental conditions such as temperature, UV exposure, and chemical exposure when choosing the appropriate type of GRP pipe seal.

- Inspection and Maintenance: Regular inspections and maintenance of the seals are essential to ensure their continued effectiveness over time.

Conclusion:

GRP pipe seals play a vital role in maintaining the integrity of GRP pipelines across various industries. Their resistance to corrosion, flexibility, and sealing effectiveness make them indispensable components for preventing leaks and ensuring the longevity of pipeline systems. Proper selection, installation, and maintenance are essential for maximizing the benefits of GRP pipe seals and safeguarding critical infrastructure and processes.