Dilatation seals, also known as expansion joints or expansion seals, are essential components in various engineering and construction applications that involve the need to accommodate thermal, structural, or dynamic movements within a system. These seals are designed to bridge gaps or spaces between two adjacent components, structures, or surfaces, allowing for controlled expansion and contraction while maintaining the integrity and functionality of the system. Their primary purpose is to prevent leaks, damage, or undue stress in industrial, commercial, and infrastructure settings.

Here’s a detailed description of dilatation seals, covering their key characteristics, types, applications, and advantages:

Key Characteristics:

- Flexibility: Dilatation seals are highly flexible and can adapt to changes in temperature, pressure, or movement. This flexibility allows them to absorb and distribute stresses, preventing damage to the connected structures.

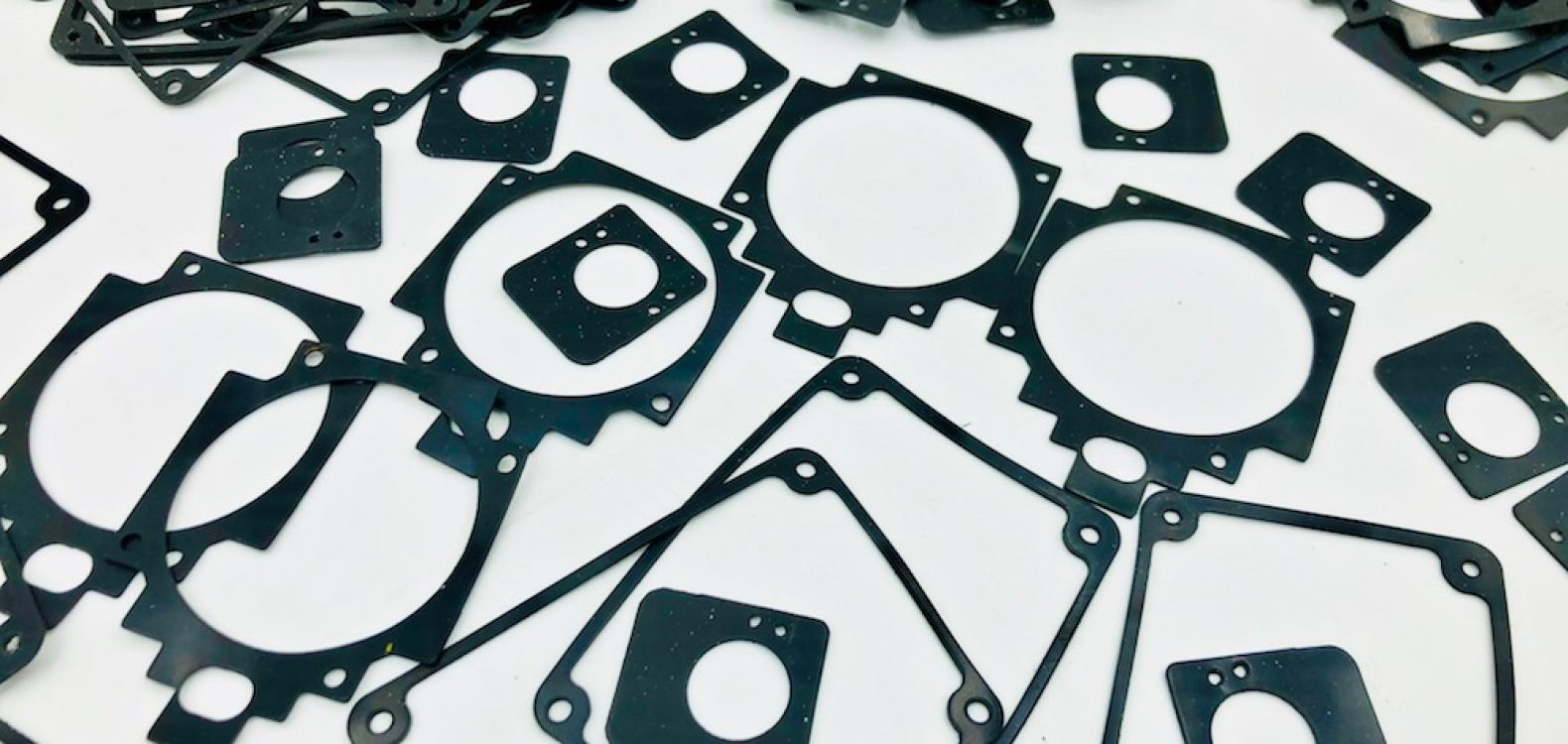

- Material Variability: These seals can be constructed from a wide range of materials, including rubber, elastomers, metal, fabric, and composite materials. The choice of material depends on the specific application’s requirements, such as temperature, chemical compatibility, and mechanical stress.

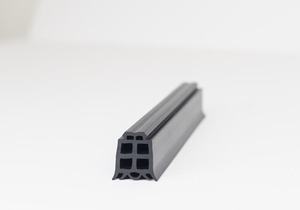

- Configurations: Dilatation seals come in various shapes and configurations, including bellows, single or multiple arches, corrugated, or flat designs. The selection of the appropriate configuration depends on the system’s design and movement requirements.

- Size and Capacity: They can be customized to accommodate various sizes and capacities, from small seals used in automotive exhaust systems to large-scale seals in bridges, pipelines, or industrial machinery.

Types of Dilatation Seals:

- Expansion Joints: These are typically used in pipelines, ducts, and bridges to allow for thermal expansion and contraction, as well as seismic movements. They are available in various designs, including axial, lateral, angular, and universal expansion joints.

- Bridge Expansion Joints: These are specifically designed for bridge structures, where they absorb movements caused by temperature fluctuations, traffic loads, and settling of bridge components. They ensure the longevity and safety of bridges.

- Metal Bellows Expansion Joints: These are often used in high-temperature and high-pressure environments, such as power plants and industrial processes. They are capable of accommodating axial, lateral, and angular movements while maintaining a hermetic seal.

- Rubber Expansion Joints: These are commonly used in water and wastewater systems, HVAC systems, and other applications where the focus is on absorbing vibrations and providing flexibility to the system.

Applications:

Dilatation seals find widespread use in numerous applications, including:

- Pipelines: They are crucial for preventing leakage and maintaining the integrity of pipelines that transport fluids or gases. This includes oil and gas pipelines, water distribution systems, and chemical processing facilities.

- Bridges and Infrastructure: Dilatation seals in bridges allow for expansion and contraction due to temperature changes and traffic loads. They protect the structure from damage and extend its service life.

- Industrial Machinery: In industrial settings, these seals are used in equipment such as turbines, pumps, and compressors to handle thermal expansion and vibration.

- Aerospace: In aerospace engineering, expansion joints are used to accommodate structural movements and temperature variations in aircraft, spacecraft, and launch facilities.

- Automotive: In automotive applications, dilatation seals are used in exhaust systems to handle the expansion and contraction of exhaust components due to temperature fluctuations.

Advantages:

- Prevent Leaks: Dilatation seals effectively prevent the escape of fluids, gases, or other substances, reducing the risk of environmental contamination and system failure.

- Extend Service Life: By absorbing and distributing stress and movement, these seals help extend the service life of structures and equipment.

- Safety: In the case of bridges and infrastructure, dilatation seals play a vital role in ensuring the safety of the public by preventing structural damage.

- Efficiency: They contribute to the efficiency of various systems by reducing energy losses and minimizing maintenance requirements.

In conclusion, dilatation seals are indispensable components in engineering and construction, providing flexibility, safety, and longevity to a wide range of systems and structures. Their ability to accommodate movements and changes in temperature and pressure makes them critical in ensuring the reliability and performance of diverse applications across industries.