Establishing a Dilatation Seals Factory: Comprehensive Overview

Introduction:

Building and operating a dilatation seals factory is a complex undertaking that involves various aspects, including location selection, facility design, production processes, quality control, and distribution. This comprehensive description will guide you through the essential steps and considerations involved in setting up and running a dilatation seals manufacturing facility.

1. Market Research and Business Plan:

- Market Analysis: Begin by conducting thorough market research to understand the demand for dilatation seals in your target region or industry. Identify potential competitors, market trends, and customer needs.

- Business Plan: Develop a detailed business plan outlining your factory’s goals, target markets, production capacity, and financial projections. This plan will serve as a roadmap for your factory’s growth and success.

2. Legal and Regulatory Compliance:

- Business Registration: Register your factory as a legal entity, such as a limited liability company (LLC) or corporation, and obtain all necessary permits and licenses.

- Quality Standards: Familiarize yourself with industry-specific quality standards and certifications, such as ISO 9001, to ensure your products meet the required specifications.

3. Location Selection:

- Accessibility: Choose a location that offers good transportation access for both raw materials and finished products. Proximity to suppliers and customers can also be advantageous.

- Infrastructure: Ensure that the chosen site has adequate infrastructure, including utilities like water, electricity, and natural gas.

- Zoning and Regulations: Verify that the location complies with zoning regulations and environmental requirements, as manufacturing processes may involve various materials and emissions.

4. Facility Design and Construction:

- Factory Layout: Plan the layout of your facility, considering the flow of materials and production processes. Allocate space for raw material storage, production lines, quality control, and packaging.

- Equipment and Machinery: Invest in suitable machinery and equipment for dilatation seal manufacturing. This may include presses, molds, cutting machines, and quality testing tools.

- Safety Measures: Prioritize safety by implementing safety protocols, emergency response plans, and providing necessary safety equipment for employees.

5. Raw Materials and Supply Chain:

- Raw Material Sourcing: Establish a reliable supply chain for the raw materials required in dilatation seal production. Consider quality, cost, and proximity when selecting suppliers.

- Inventory Management: Implement an efficient inventory management system to ensure a steady supply of materials while minimizing excess stock.

6. Production Processes:

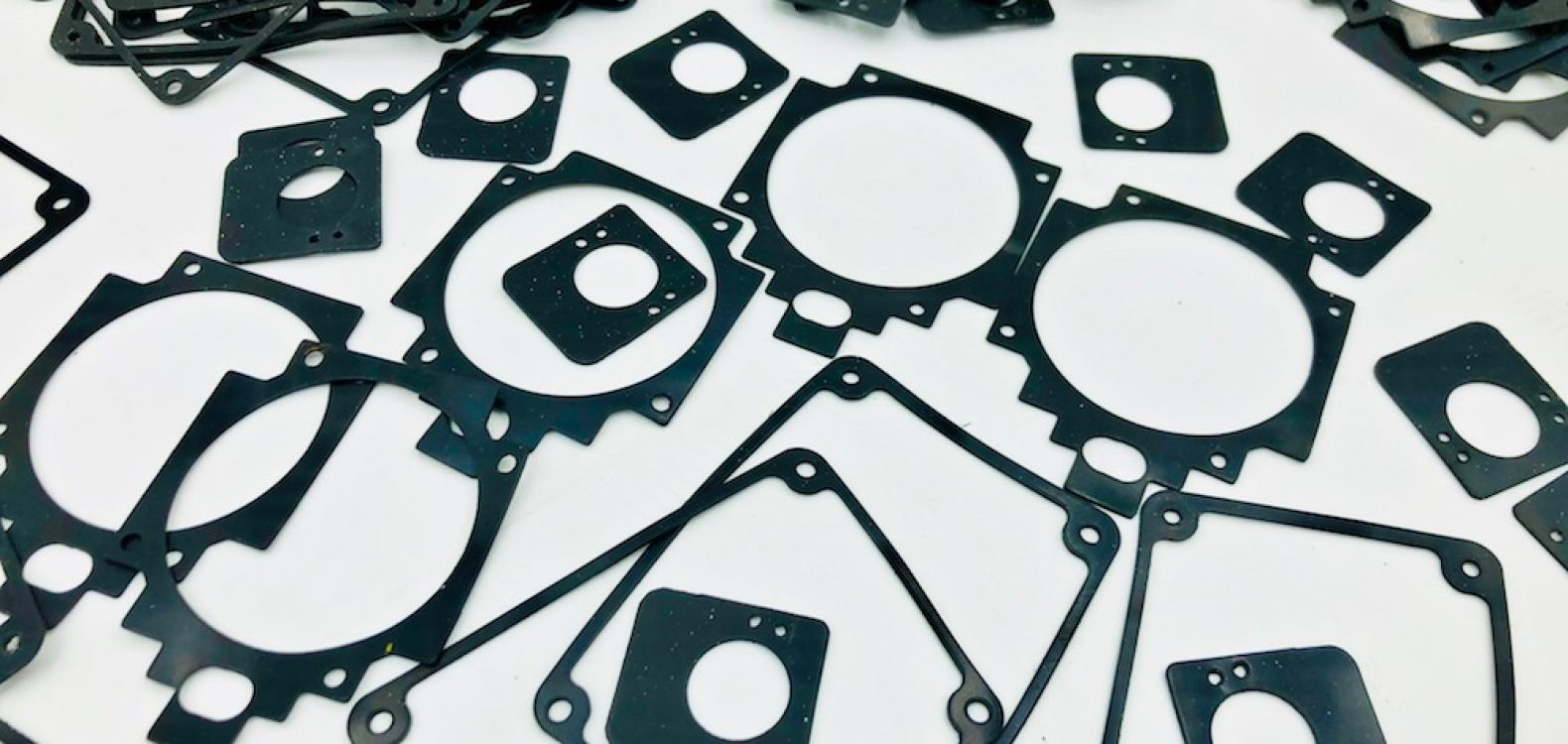

- Product Design: Develop a range of dilatation seal designs tailored to meet different industry and application requirements.

- Manufacturing Processes: Implement production processes that include material preparation, molding, curing, quality testing, and packaging. Ensure consistent quality control throughout.

- Employee Training: Train your workforce on the manufacturing processes, safety procedures, and quality standards. Skilled and knowledgeable employees are crucial for product quality.

7. Quality Control and Testing:

- Quality Assurance: Set up a dedicated quality control department to inspect, test, and certify your dilatation seals for compliance with industry standards and customer expectations.

- Product Testing: Conduct rigorous testing, including pressure testing, temperature resistance, and durability assessments, to ensure product reliability.

8. Marketing and Sales:

- Marketing Strategy: Develop a marketing strategy that includes online and offline channels to reach potential customers. Highlight the quality, features, and applications of your dilatation seals.

- Sales Channels: Establish relationships with distributors, wholesalers, and direct customers to expand your market reach.

9. Distribution and Logistics:

- Distribution Network: Set up an efficient distribution network to deliver products to customers promptly. Consider warehousing options if necessary.

- Logistics Management: Optimize logistics processes to minimize shipping costs and delivery times.

10. Sustainability and Environmental Responsibility:

- Green Practices: Implement eco-friendly practices in your factory, such as recycling waste materials and minimizing environmental impact.

- Compliance: Ensure that your operations comply with environmental regulations and standards.

11. Financial Management:

- Budgeting: Maintain a detailed budget to track expenses, revenue, and profitability. Periodically review and adjust your financial plan as needed.

- Cost Control: Implement cost-control measures to maximize profitability without compromising product quality.

12. Expansion and Growth:

- Scaling Up: As demand grows, consider expanding your production capacity, exploring new product lines, or entering new markets.

- Research and Development: Invest in research and development to innovate and improve your dilatation seals, staying competitive in the market.

Conclusion:

Starting and operating a dilatation seals factory is a multifaceted endeavor that requires careful planning, adherence to quality standards, and continuous improvement. By following these steps and maintaining a commitment to quality and customer satisfaction, you can build a successful and sustainable business in the dilatation seal manufacturing industry.