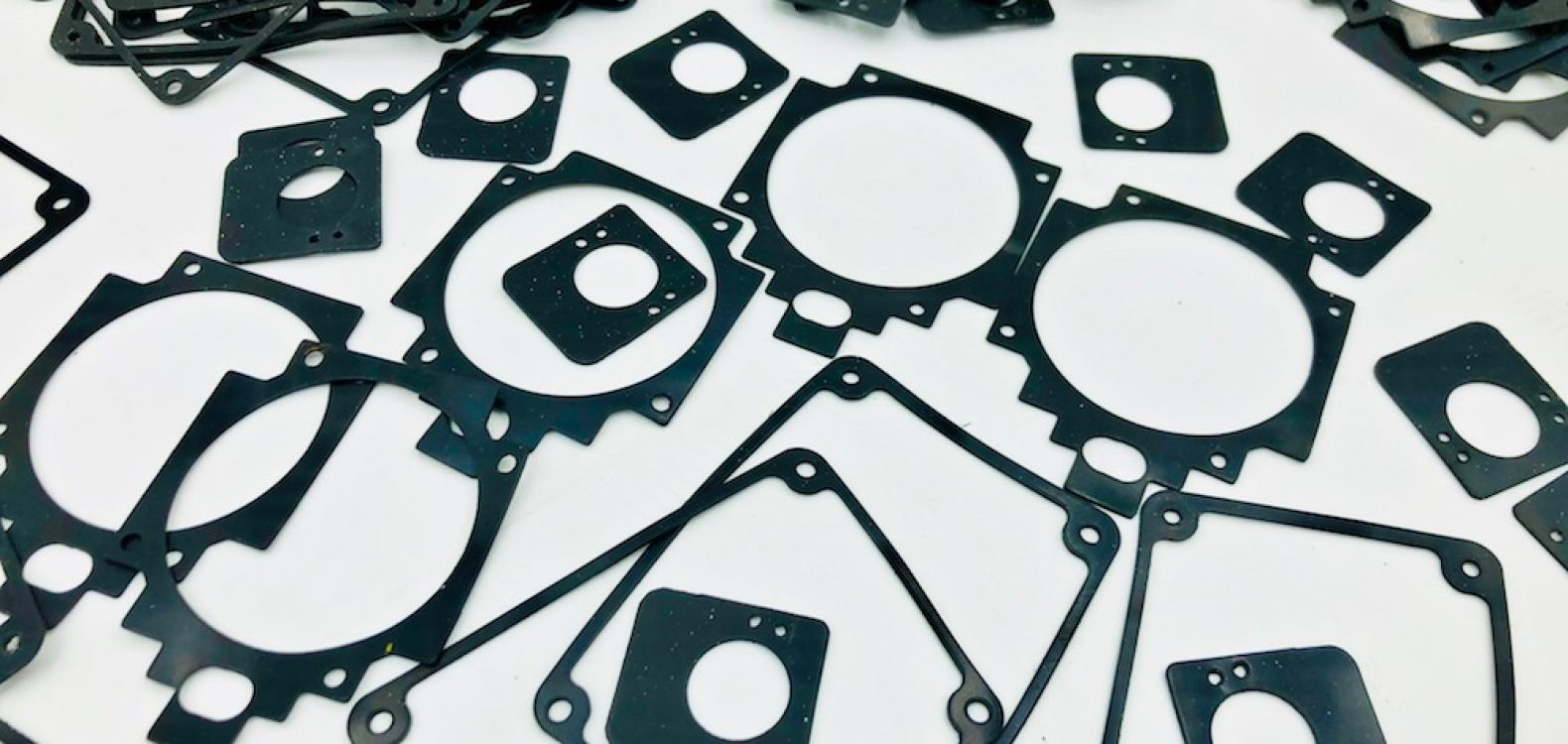

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are widely used sealing components known for their excellent weather resistance, durability, and versatility. These gaskets are commonly used in various industries and applications due to their ability to provide effective seals against moisture, chemicals, temperature fluctuations, and UV exposure. Here’s an overview of EPDM rubber gaskets:

Key Characteristics of EPDM Rubber Gaskets:

- Excellent Weather Resistance: EPDM gaskets are highly resistant to weathering, ozone, and UV radiation. This makes them suitable for outdoor applications, such as in construction, automotive, and HVAC systems.

- Chemical Resistance: EPDM rubber exhibits good resistance to a wide range of chemicals, including acids, bases, and some solvents. This chemical resistance makes EPDM gaskets suitable for use in various industrial environments.

- Temperature Tolerance: EPDM gaskets have a broad temperature range, typically from -40°C to 120°C (-40°F to 248°F), although specific formulations may extend this range. They maintain their elasticity and sealing properties over a wide temperature spectrum.

- Flexibility and Elasticity: EPDM rubber is highly flexible and elastic, allowing it to conform to irregular surfaces and provide an effective seal even in challenging applications.

- Water and Steam Resistance: EPDM gaskets are widely used in plumbing and steam systems because they maintain their sealing properties when exposed to hot water and steam.

- Low Electrical Conductivity: EPDM rubber has low electrical conductivity, which is advantageous in applications where electrical insulation is required.

Applications of EPDM Rubber Gaskets:

EPDM rubber gaskets find applications in a wide range of industries and sectors, including:

- Automotive: EPDM gaskets are used in automotive components such as door seals, window seals, and under-the-hood gaskets to provide weatherproofing and sealing against moisture and noise.

- Construction: EPDM gaskets are used in building and construction for sealing doors, windows, and roofing systems to prevent water infiltration and ensure energy efficiency.

- HVAC Systems: EPDM gaskets are employed in heating, ventilation, and air conditioning (HVAC) systems for sealing ductwork, joints, and access panels.

- Plumbing: EPDM gaskets are used in plumbing systems, including pipe couplings, valves, and fittings, to create watertight seals.

- Electrical Enclosures: They are used in electrical enclosures to provide gasketing and environmental protection.

- Marine and Nautical: EPDM gaskets are suitable for marine applications due to their resistance to saltwater and UV exposure.

- Industrial Machinery: EPDM gaskets are used in various industrial equipment and machinery, particularly where resistance to chemicals and temperature extremes is required.

- Aerospace: In the aerospace industry, EPDM gaskets are used in applications such as aircraft door seals and gaskets for critical systems.

Installation Considerations:

- Proper surface preparation is essential for ensuring a secure and effective seal.

- Follow the manufacturer’s guidelines for the correct torque or compression level when installing gaskets.

- Regular inspections and maintenance help prolong the lifespan and effectiveness of EPDM rubber gaskets.

In summary, EPDM rubber gaskets are versatile sealing components known for their resilience, durability, and resistance to environmental factors. They are widely used across industries to create effective seals in various applications, from automotive to construction and beyond.