Dilatation seals, also known as expansion joints, are vital components used in various engineering and construction applications to accommodate the expansion and contraction of structures, machinery, or pipelines due to temperature variations, seismic activity, settlement, or other factors. These flexible connectors play a critical role in maintaining the structural integrity, safety, and functionality of various systems and structures. In this detailed description, we will explore the various aspects of dilatation seals, including their types, materials, functions, and applications.

1. Types of Dilatation Seals:

Dilatation seals come in various types, each designed to address specific needs and movement requirements. Some common types include:

- Expansion Bellows: These are often accordion-like structures made from materials such as rubber, metal, or fabric. Expansion bellows provide flexibility to accommodate axial, lateral, and angular movements in piping systems and industrial machinery.

- Modular Expansion Joints: Modular expansion joints consist of multiple individual sections that can be assembled to create expansion joints of varying lengths. They are commonly used in bridge construction and large industrial facilities.

- Strip Seals: Strip seals consist of a series of steel strips and rubber inserts. They are used in bridge expansion joints and are effective in accommodating moderate movements.

- Compression Seals: Compression seals are used to fill the gap between two adjacent structural elements, like bridge deck segments. They are compressed as the structure expands and expands as it contracts.

- Pipe Expansion Joints: These are used in piping systems to absorb thermal expansion and contraction, as well as other movements that may occur in the system. They come in various designs, including single and multiple bellows types.

2. Materials:

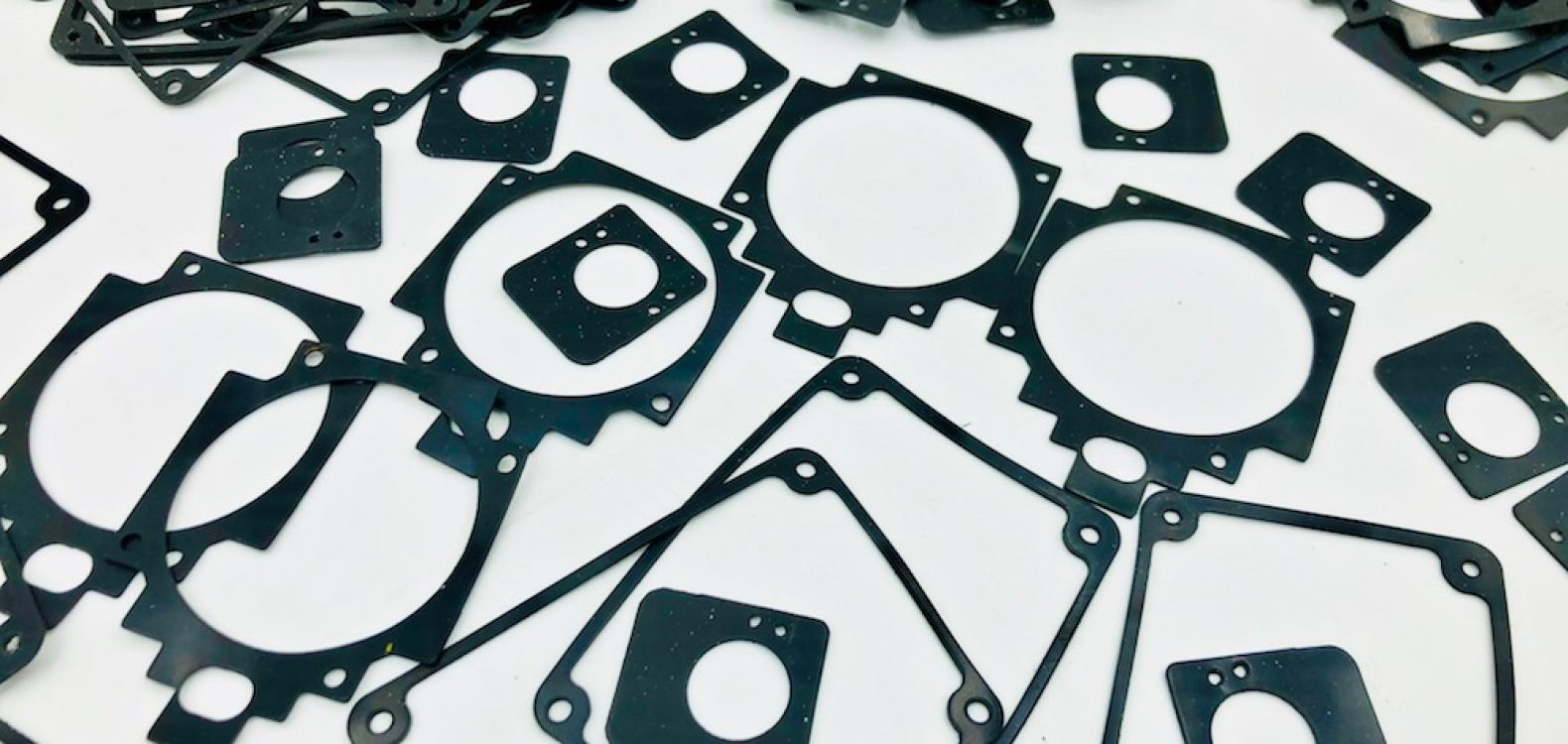

Dilatation seals can be constructed from a variety of materials, depending on the specific requirements of the application:

- Rubber: Natural rubber or synthetic elastomers like neoprene and EPDM are commonly used in expansion joints for their flexibility, durability, and resistance to weather and chemicals.

- Metal: Various metals, including stainless steel, carbon steel, and aluminum, are used in expansion joints to provide strength and resistance to high temperatures and corrosion.

- Fabric: High-strength fabrics such as nylon or polyester can be used in fabric expansion joints for applications involving large movements.

- Composite Materials: Some expansion joints use composite materials, which combine the benefits of different materials to meet specific needs, such as flexibility, durability, and resistance to harsh environments.

3. Functions:

Dilatation seals serve several essential functions, including:

- Accommodating Movement: They absorb and accommodate movements caused by temperature fluctuations, settling, seismic activity, or other factors, preventing structural damage or failure.

- Sealing Against Environmental Factors: Expansion joints help seal gaps between adjacent structural elements, preventing the infiltration of water, dust, and debris, which can lead to corrosion and deterioration.

- Reducing Vibration and Noise: In industrial applications, dilatation seals can reduce the transmission of vibrations and noise, improving the overall safety and comfort of the environment.

- Safety and Longevity: By accommodating movements and sealing gaps, expansion joints contribute to the safety and longevity of structures, reducing maintenance costs and the risk of structural failure.

4. Applications:

Dilatation seals find use in a wide range of applications, including:

- Bridges: Expansion joints are crucial in bridge construction, allowing the bridge to expand and contract with temperature changes and seismic activity while maintaining its structural integrity.

- Buildings: They are used in building construction to accommodate movements between various structural elements, such as floors, walls, and roofs.

- Industrial Facilities: Expansion joints are used in industrial settings to absorb movements in equipment, piping systems, and other structures.

- Pipelines: In the oil and gas industry, dilatation seals are used in pipelines to accommodate thermal expansion and contraction.

- Highways and Roads: Expansion joints in roadways allow for movement caused by temperature changes and traffic loads, extending the lifespan of the infrastructure.

- Railroads: Expansion joints in railway tracks provide flexibility to absorb movements and vibrations caused by passing trains.

In conclusion, dilatation seals, or expansion joints, are essential components in engineering and construction, providing flexibility and sealing solutions that accommodate movements and ensure the safety, longevity, and functionality of structures and systems. The wide variety of seal types, materials, and applications highlights their versatility in addressing the dynamic needs of modern construction and industrial projects. Whether in bridges, buildings, industrial facilities, or pipelines, dilatation seals play a crucial role in maintaining structural integrity and safety.