Concrete pipe seals, often referred to as concrete pipe gaskets or concrete pipe joints, are specialized components used in the construction and maintenance of concrete pipes. These seals play a critical role in ensuring the integrity of concrete pipe systems by creating watertight and secure connections between pipe segments. Here’s an overview of concrete pipe seals:

Key Features of Concrete Pipe Seals:

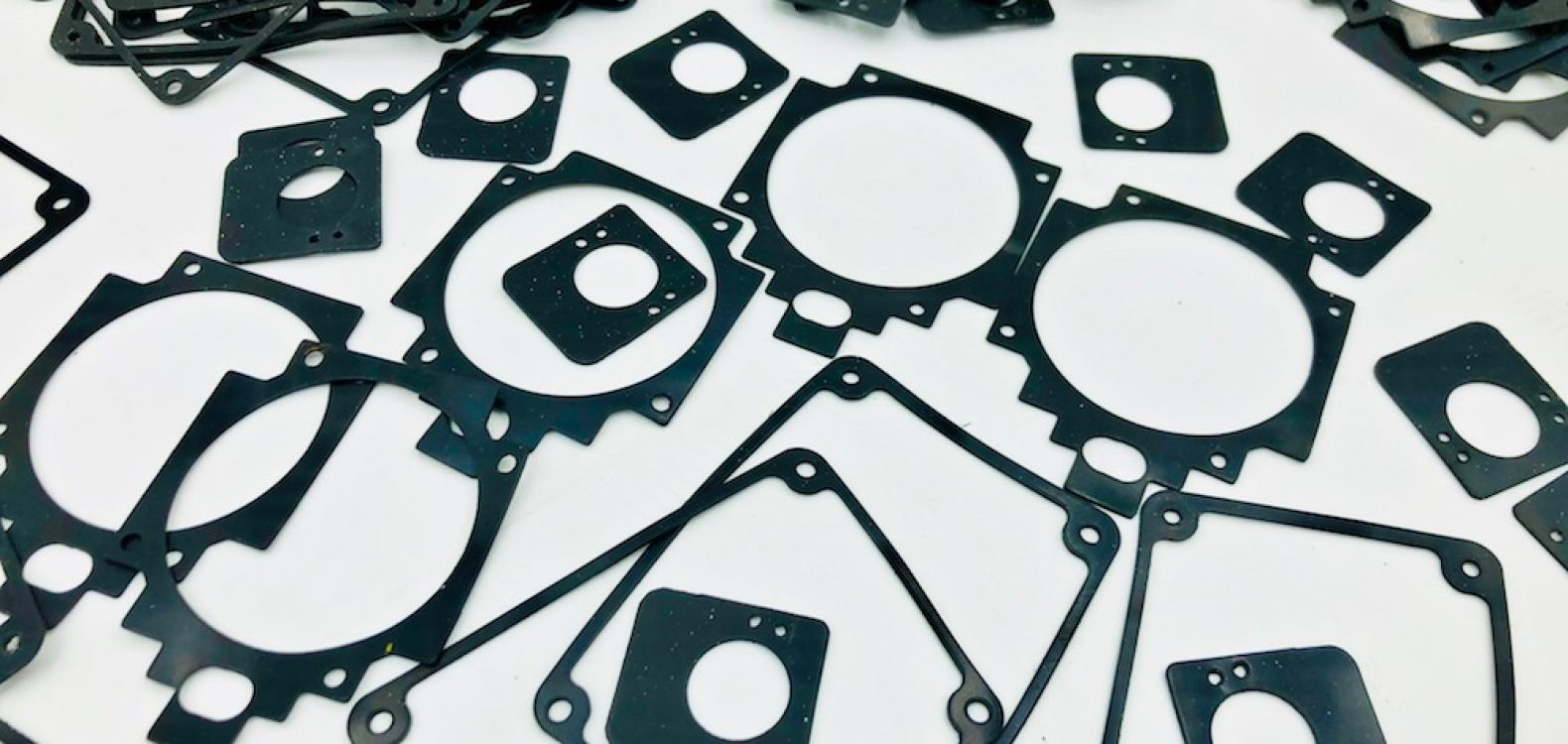

- Material Composition: Concrete pipe seals are typically made from resilient elastomeric materials such as rubber or synthetic rubber compounds. These materials provide flexibility, durability, and resistance to water, chemicals, and environmental factors.

- Profile Design: The seals are designed with specific profiles or shapes that allow them to create a secure and watertight connection between concrete pipe segments. Common profiles include O-rings, gaskets, and lip seals.

- Compression Resistance: Concrete pipe seals are designed to withstand the compression forces generated during the installation and use of concrete pipes. They maintain their shape and sealing properties under pressure.

- Corrosion Resistance: The elastomeric materials used in these seals are resistant to corrosion, making them suitable for use in wastewater, stormwater, and other corrosive environments.

- Temperature Resistance: Concrete pipe seals can withstand a range of temperatures, making them suitable for both hot and cold water applications.

Advantages of Concrete Pipe Seals:

- Watertight Sealing: The primary function of concrete pipe seals is to create a watertight seal between concrete pipe segments, preventing leaks and ensuring the efficient conveyance of fluids.

- Chemical Resistance: These seals are resistant to a wide range of chemicals commonly found in wastewater and drainage systems, which helps prolong their lifespan.

- Durability: Concrete pipe seals have a long service life and provide reliable performance, reducing the need for frequent maintenance or replacements.

- Easy Installation: They are relatively easy to install, contributing to cost-effective construction and repairs of concrete pipe systems.

Applications of Concrete Pipe Seals:

- Wastewater Systems: Concrete pipe seals are widely used in wastewater collection and treatment systems, including sewage pipes, manholes, and stormwater drainage systems.

- Culverts and Drainage Systems: They are employed in culverts and various drainage systems to prevent water infiltration or exfiltration and maintain proper drainage.

- Infrastructure Projects: Concrete pipe seals are used in infrastructure projects such as road construction, bridges, and tunnels for drainage and sewage systems.

Installation Considerations:

- Proper Fit: Ensure that the seal is correctly sized and designed to match the dimensions and profile of the concrete pipe joint for a secure fit.

- Clean Surfaces: Before installation, clean the pipe ends and sealing surfaces to remove debris and ensure a clean and smooth mating surface.

- Lubrication: Lubricate the seal with a compatible lubricant to facilitate ease of installation and ensure a proper seal.

In summary, concrete pipe seals are essential components in concrete pipe systems, providing watertight seals and ensuring the efficient conveyance of fluids. Proper selection, installation, and maintenance of these seals are crucial to the long-term reliability of concrete pipe systems in various applications.